From Algorithm development to Industrial product

Challenge

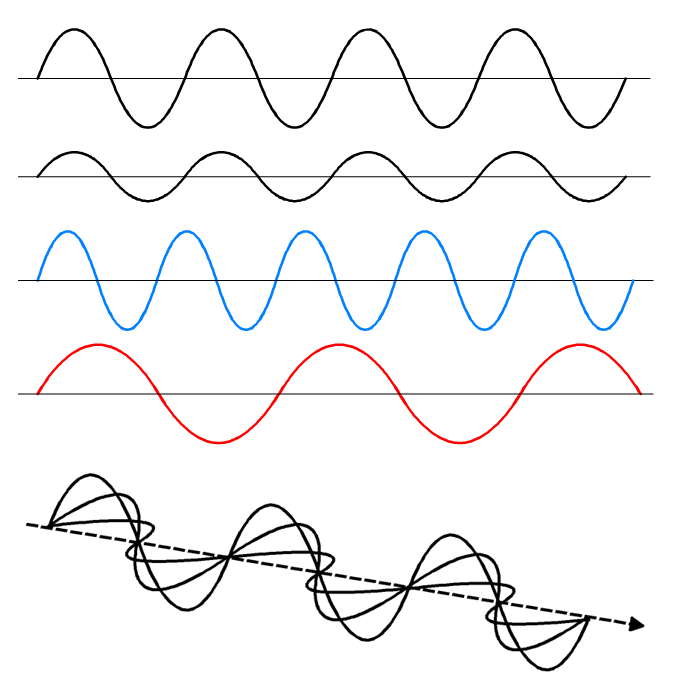

Light is an electromagnetic wave, with

- Amplitude perceived as brightness

- Wavelength perceived as color

- But the orientation of the

wave oscillation is not visible

Properties of Polarization:

- All orientations equally present

--> degree of polarization 0% - Only one strong orientation

--> degree of polarization 100% - All orientations are present

but at different strength

--> partially polarized, e.g. 50% - Dominant angle of polarization

--> another degree of freedom

Where does it come from?

Most light sources (except lasers) are unpolarized

- Reflection gives polarized light, think of water surfaces, glass, beamsplitters surface inspection, ellipsometry

- Reflection at non-metallic surfaces like human skin, plants, plastics, object classification

-

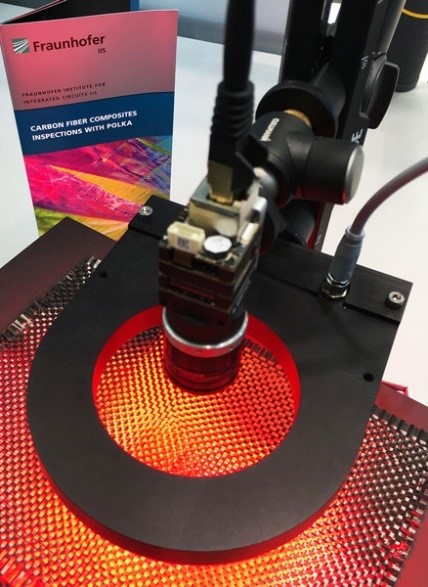

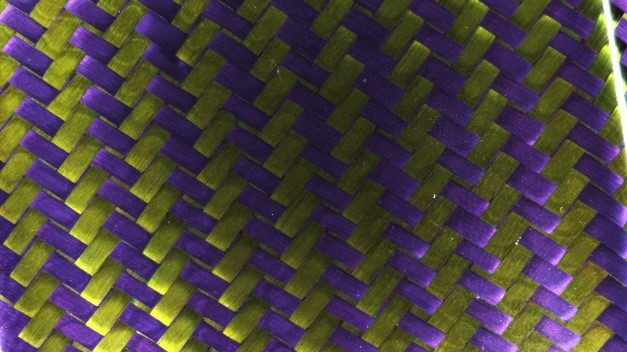

Nanostructures can create polarization in transmission and reflection, useful for polarization filters, carbon fiber inspection

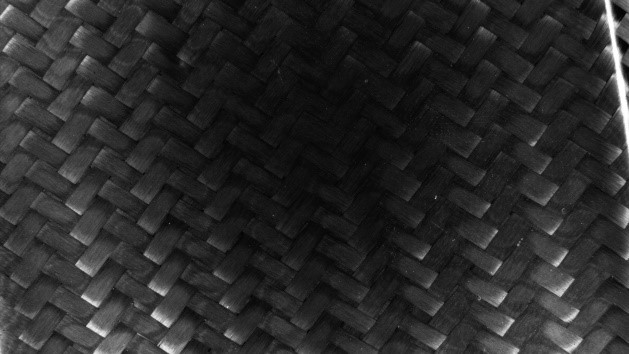

Application to Carbon Fiber Reinforced Plastics (CFRP) Inspection

Without polarization

With polarization

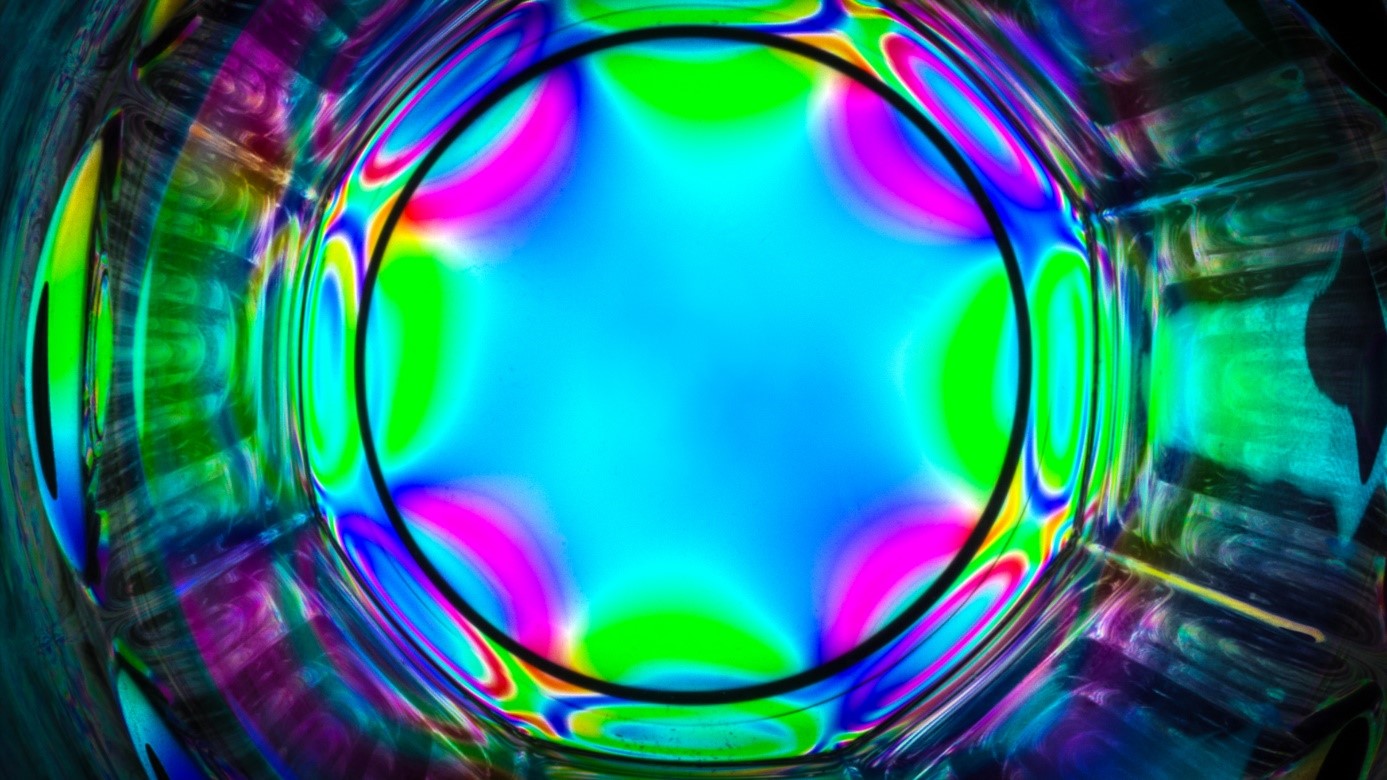

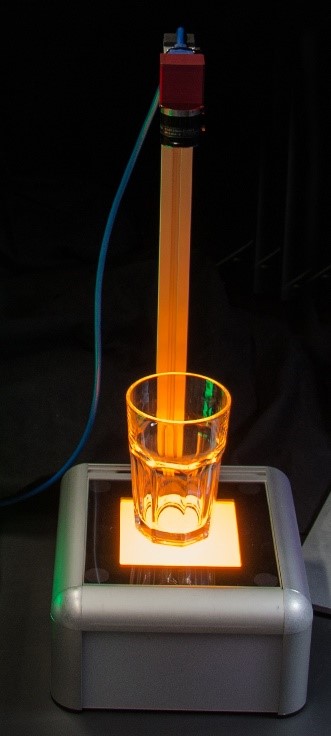

Application to Stress Inspection in Glass

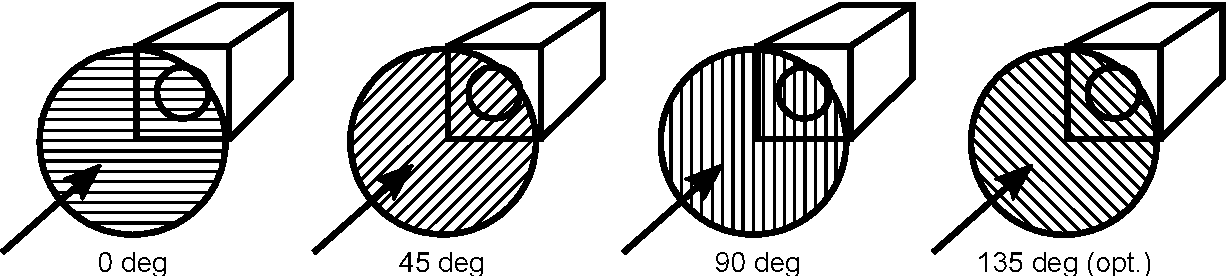

Measuring Polarization

- Polarization has 3/4 degrees of freedom

- Intensity of light

- Degree of polarization

- Angle of maximum polarization

- (Circularity)

We can use ≥3 measurement with polarization filters for analysis

(and some math to obtain Stokes parameters)

But from there:

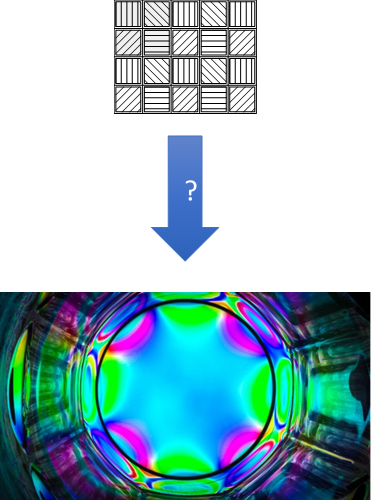

- How to process the raw sensor data?

- Different from RGB debayering

- How do you calibrate measurements?

- Achieving reliable data for measurements

- How to solve the applications

- What is a good setup?

- The user does not need polarization values

- More processing is required to calssify

industrial products for quality (good/bad)

Solution

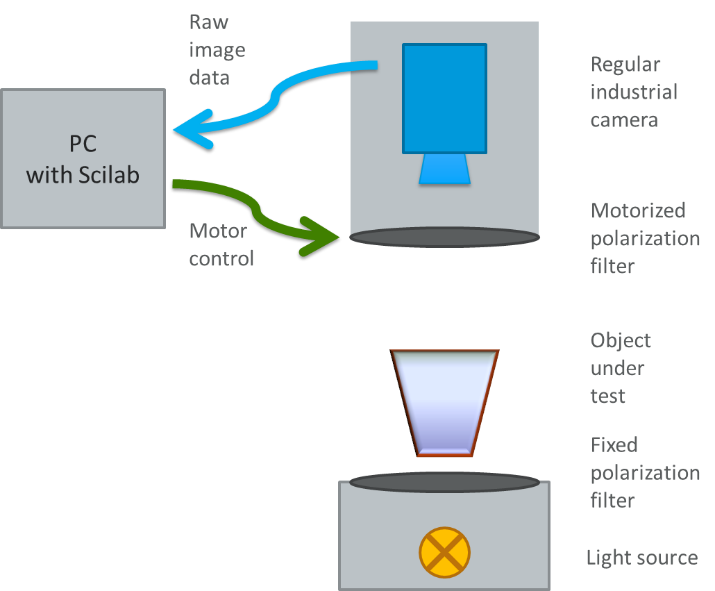

Algorithm development with internal prototype camera

- Image processing for evaluating

different modes/calculations - Extending SciLab

- Interfacing an industrial USB

camera for live image capture - Interfacing a step motor controller

for defined filter rotation

- Interfacing an industrial USB

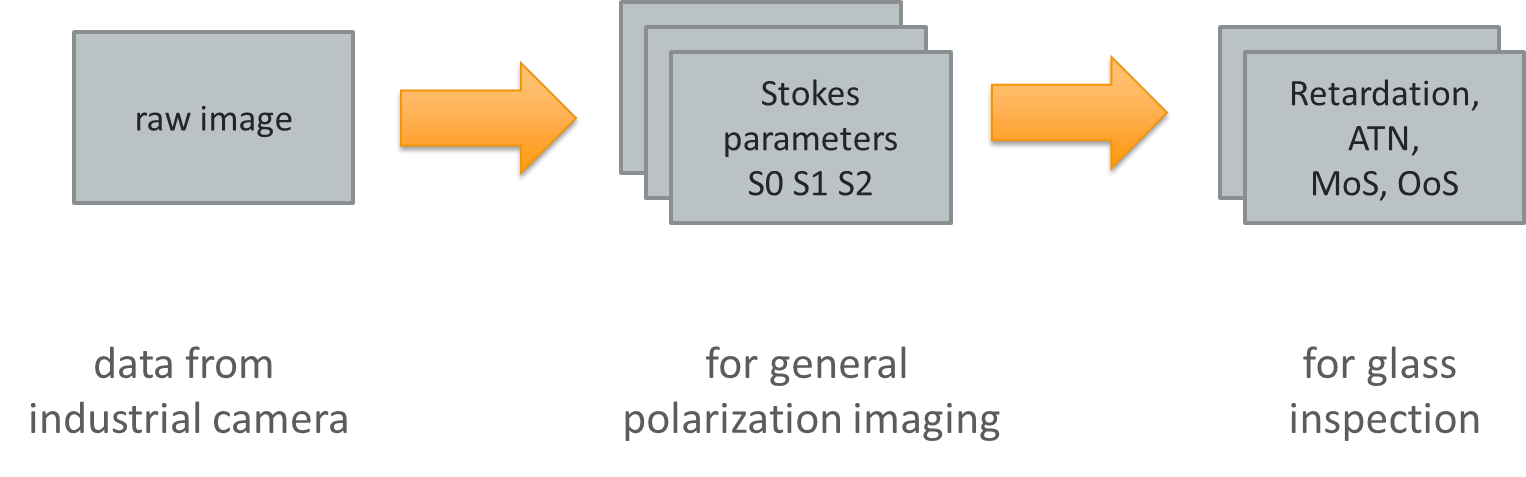

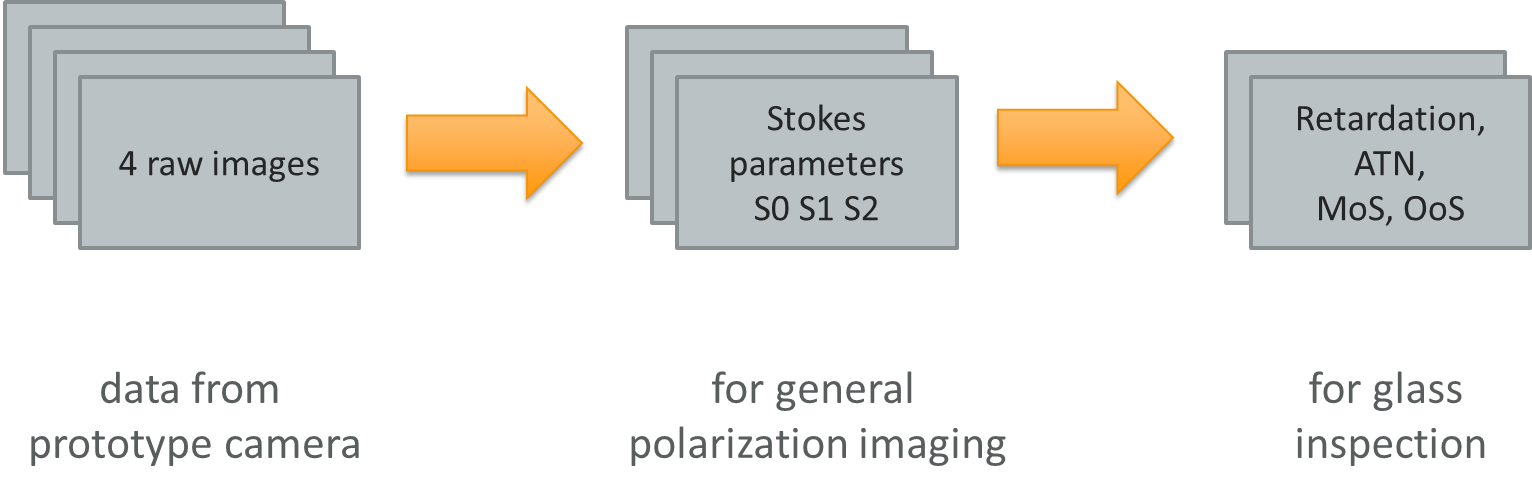

Processing Stack for Prototype System

Results

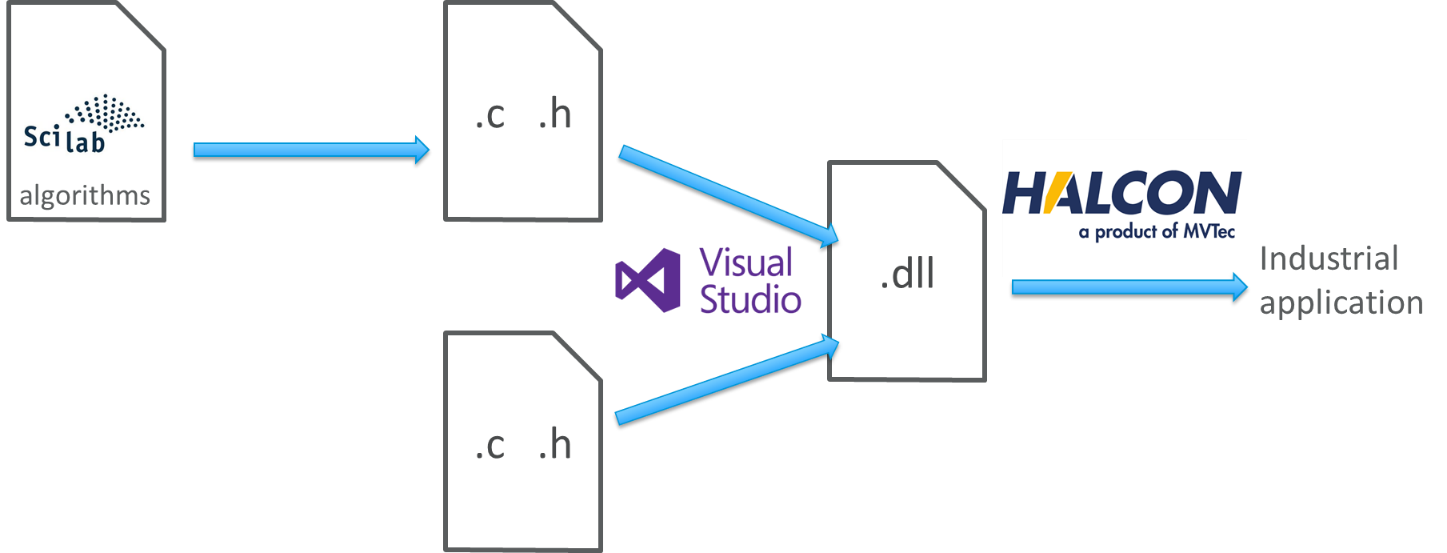

Product Development: For integration into industrial inspection systems

- Use upcoming industrial cameras

- 5 MPixel, single-shot imaging

- High frame rate for inline inspection

- Provide the software as extension/plugin/.dll

for machine vision software - Calibrated measurements of retardation/ATN

- Measurement of magnitude and orientation of stress

From Scilab Code to a .dll

Re-programm everything again- Transfer into parallel C code

- Utilize parallel architectures

- Take into account:

- Worst-case execution time

- hard realtime applications

Toolflow used

Processing Stack for Commercial Solution